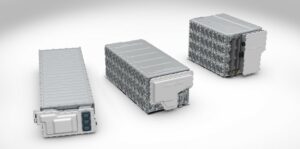

MAN Truck & Bus sees the greatest potential for climate-friendly drives in battery electric drives. And although the market for electrically driven city buses and, in future, also trucks, is only just developing in Europe, the Munich-based commercial vehicle manufacturer is already working on the post-usage strategy for its batteries. The aim is to extend the life of the batteries in the first step and, if this is no longer possible, to recycle the raw materials contained in them.

The transformation of the commercial vehicle industry to zero-emission drives has begun. Battery electric drives will be the key technology of the future. However, it will take a few more years before these BEVs (Battery Electric Vehicles) will become the norm on the roads – and not the exception.

In the truck sector, MAN Truck & Bus currently expects that electric trucks will have a share of 60% in distribution applications and 40% in long-haul transport in 2030.

Electrification of city buses began earlier, with MAN expecting 50% of sales to be electric drives by 2025. These forecasts show that the commercial vehicle industry is only at the beginning of electrification. The number of batteries that have come to the end of their service life in vehicles will therefore only reach industrial levels in around 10 to 15 years.

Electrification of city buses began earlier, with MAN expecting 50% of sales to be electric drives by 2025. These forecasts show that the commercial vehicle industry is only at the beginning of electrification. The number of batteries that have come to the end of their service life in vehicles will therefore only reach industrial levels in around 10 to 15 years.

However, MAN is already working on developing a strategy for how the valuable batteries can be used in a resource-conserving manner in secondary applications.

The analysis starts with the first life of the battery in the vehicle: The focus here is on training customers to drive, charge and use the vehicles so that the load on the battery is minimised. This can significantly increase the service life of the battery.

If parts of the battery pack suffer a defect during use, e.g. individual modules no longer function, repair of the battery is planned as a first measure. The battery can then be used again in the vehicle.